Product Description:

The Conveyor Belt Vulcanizer is a cutting-edge Belt Splicing Equipment designed to efficiently connect conveyor belts with precision and durability. Featuring a temperature range of 0-200℃, this vulcanizer ensures optimal conditions for splicing operations, allowing for seamless belt connections that can withstand the rigors of industrial applications.

With a curing temperature range of 145-199 degrees, the Conveyor Belt Vulcanizer provides the ideal heat levels required for the vulcanization process, ensuring strong and reliable belt joints. The precise control over the curing temperature enhances the overall quality and longevity of the spliced belts, making them highly resilient to wear and tear.

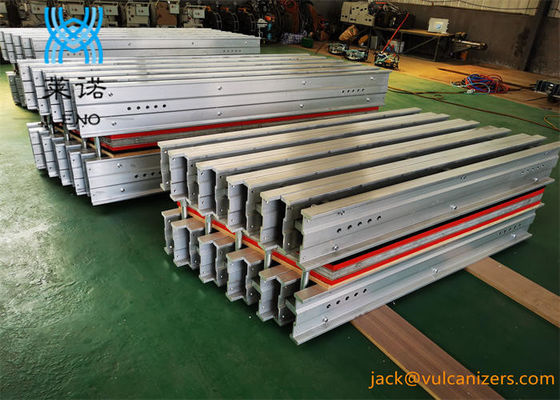

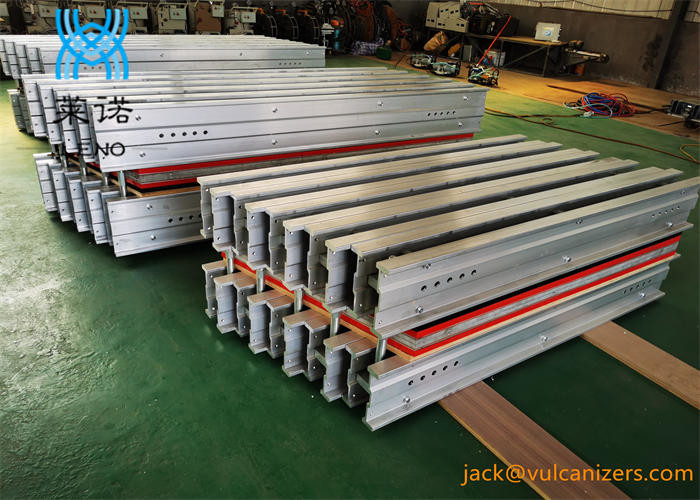

Constructed with High Strength Aluminum Alloy pressure bars, this Belt Connecting Equipment offers exceptional durability and stability during the splicing process. The robust material ensures that the pressure applied during vulcanization is uniform and consistent, resulting in high-quality belt joints that maintain their integrity under heavy loads.

The Conveyor Belt Vulcanizer is equipped with a heating element made of flexible silicone, providing efficient and uniform heat distribution across the splicing area. The light model design of the heating element enhances the portability and ease of use of the vulcanizer, making it suitable for various on-site splicing applications.

Featuring an Automatic Control Box, this Belt Splicing Equipment offers user-friendly controls for monitoring and adjusting the vulcanization process. The automatic control system enables precise regulation of temperature, pressure, and other parameters, ensuring accurate and repeatable splicing results with minimal manual intervention.

Whether in mining, manufacturing, or logistics operations, the Conveyor Belt Vulcanizer delivers reliable performance and exceptional efficiency in connecting conveyor belts. Its advanced features and robust construction make it an essential tool for maintaining conveyor systems and ensuring smooth material handling processes.

Features:

-

Product Name: Conveyor Belt Vulcanizer

-

Usage: Belt Joint

-

Control Monitor: Automatic Control Box

-

Pressure Bar Material: High Strength Aluminum Alloy

-

Temperature: 0-200℃

-

Heating Element: Flexible Silicone, Light Model

Technical Parameters:

|

Pressure Bar Material

|

High Strength Aluminum Alloy

|

|

Curing Temperature

|

145-199 Degree

|

|

Control Monitor

|

Automatic Control Box

|

|

Usage

|

Belt Joint

|

|

Temperature

|

0-200℃

|

|

Heating Element

|

Flexible Silicone, Light Model

|

Applications:

The Conveyor Belt Vulcanizer is a versatile and essential tool designed for various product application occasions and scenarios. With its unique attributes and features, this equipment is ideal for a wide range of industries and settings.

One of the key product attributes of the Conveyor Belt Vulcanizer is its curing temperature range of 145-199 degrees. This makes it perfect for rubber vulcanizing press applications where precise temperature control is crucial for achieving optimal results. Whether you are working on conveyor belts in mining operations, agricultural facilities, or manufacturing plants, this machine ensures efficient and effective belt jointing.

The heating element of the vulcanizer is made of flexible silicone, providing uniform heat distribution across the belt splice. This light model is easy to handle and maneuver, making it suitable for on-site repairs and maintenance tasks. The temperature range of 0-200℃ allows for customization based on the specific requirements of the belt material and joint type.

When it comes to usage, the Conveyor Belt Vulcanizer is the go-to choice for belt splice pressing machine operations. Its precision engineering and automatic control box enable seamless control and monitoring of the vulcanizing process. This ensures consistent results and minimizes the risk of errors during belt jointing procedures.

Whether you are involved in heavy-duty industrial applications or routine conveyor belt maintenance, the Conveyor Belt Vulcanizer is a reliable and efficient solution. Its versatility and durability make it a must-have tool for any facility that relies on conveyor systems for material handling. Invest in this advanced equipment today and experience the difference in your belt jointing processes.

귀하의 메시지는 20-3,000 자 사이 여야합니다!

귀하의 메시지는 20-3,000 자 사이 여야합니다! 이메일을 확인하십시오!

이메일을 확인하십시오!  귀하의 메시지는 20-3,000 자 사이 여야합니다!

귀하의 메시지는 20-3,000 자 사이 여야합니다! 이메일을 확인하십시오!

이메일을 확인하십시오!